Products

Double cementing machine

Classification:

Double machine double pump equipment

Introduction

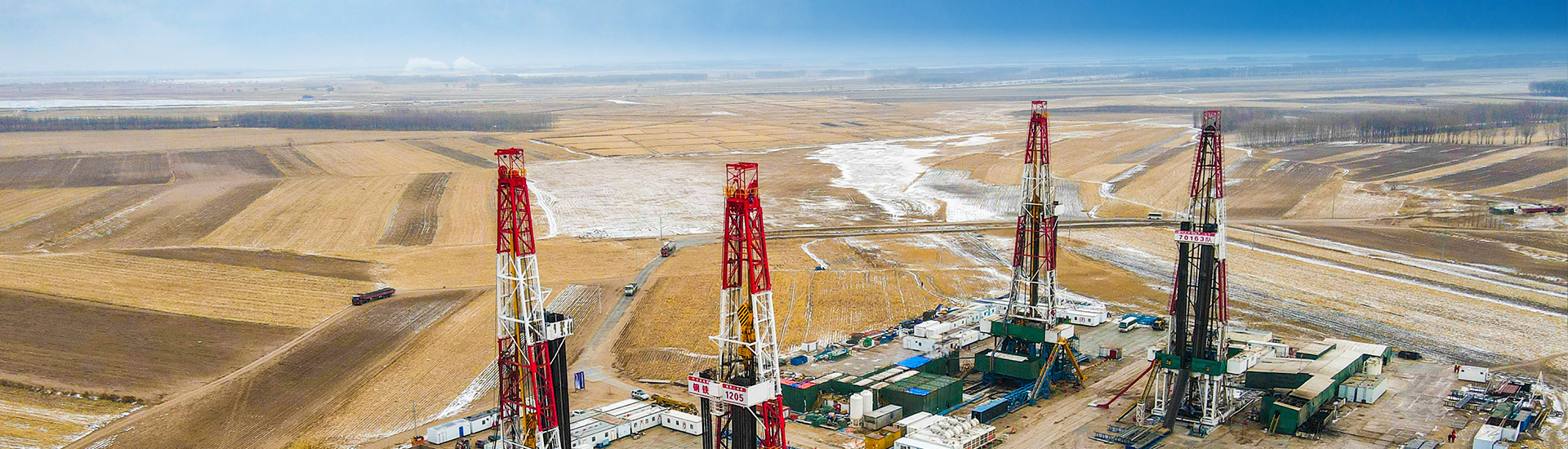

1. All-weather oilfield cementing equipment to meet the needs of different operating areas such as land, sea and desert, and adapt to harsh environments such as extreme cold and extreme heat;

2. The 12 "display screen has the function of displaying the operation data curve, which is convenient for the operator to better monitor the operation condition;

3. The operation interface and operation function keys can be modified according to the customer's operation habits, and the density control algorithm is optimized. The operation input is simple and the control is accurate and stable;

4. AMS dual-variable intelligent electronically controlled slurry mixing system, precise density control, leading the forefront of cementing mixing technology; hand automatic seamless switching of optional operation modes;

5. Professional data acquisition system to realize real-time recording, analysis and storage of cementing vehicle operation data;

6. The dual-machine and dual-pump cementing equipment realizes mutual standby of manifold and functions, making the operation safer and more reliable;

7. Adopt professional ergonomic design and safety protection system, comfortable, safe and reliable, improve product satisfaction.

| Technical parameters | ||||||||

| Mode of delivery | Vehicle-mounted/semi-trailer/skid-mounted | |||||||

| vehicle chassis | Sinotruk/Wuyue | |||||||

| Engine | DDCS60 / CAT C15 | |||||||

| Gearbox | ALLISON 4700 OFS | |||||||

| plunger pump | WL600N / WL600S | WL500W | ||||||

| Plunger diameter | 3" | 3.5" | 4" | 4.5" | 4" | 4.5" | ||

| Maximum working pressure | 97.6 MPa | 71.7 MPa | 54.9 MPa | 43.4 MPa | 98.8 MPa | 78.4 MPa | ||

| Maximum working flow | 0.9 m3/min | 1.3 m3/min | 1.7 m3/min | 2.1 m3/min | 1.2 m3/min | 1.5 m3/min | ||

| Centrifugal pump | Spraying and water supply: 4 × 3 × 13; circulation and perfusion: 6 × 5 × 11 | |||||||

| Metering tank | 2 × 12 bbl (2 × 2 m3) | |||||||

| Mixing tank | 10 bbl (1.6 m3) | |||||||

| Mixing density range | 8.3~22 ppg (1~2.6 g/cm3) | |||||||

| Max. mixing capacity | 14.5 bpm (2.3 m3/min) | |||||||

| slurry mixing system | AMS1.6 / AMS2.5 | |||||||